Resection Surveys – New Functionality in the Syncromine Survey Module

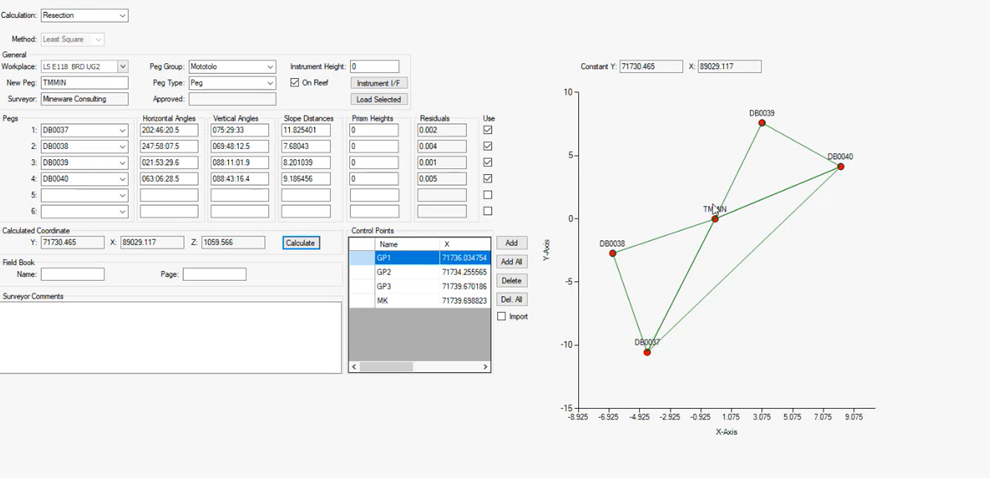

Our latest Syncromine Survey Module update introduces resection survey functionality, giving mine surveyors and civil engineers greater flexibility in the field. With this improvement, surveyors are no longer restricted to known positions – they can now set up at any point, sight known locations from anywhere, and work around obstructions without compromising accuracy. This upgrade not only streamlines survey processes, but also improves safety and efficiency, reducing the need for resurveying and ensuring more reliable results. Let’s dive in.

What’s New?

Traditionally, surveys are conducted by setting up an instrument at a known point and sighting an unknown point, allowing for forward surveying. With our new update, surveyors can now:

- Set up at any point – no longer restricted to known positions.

- Sight from anywhere to a known point for calculations.

- Utilize up to six known pegs to improve accuracy.

- Adjust for physical obstructions – if a previous setup location is no longer accessible due to ground movement or ongoing work, surveyors can reposition without disrupting the survey.

Key Benefits

- Safety : Resection or sidewall peg placement: A resection survey allows surveyors to determine their position without needing a predefined setup point, making it easier to establish survey control in areas where traditional setups might be difficult or unsafe.

- Safety: No drilling on HW (hanging wall): Drilling into the hanging wall can create instability, increasing the risk of rockfalls or collapses. By enabling resection surveys, surveyors can avoid the need to drill into these areas, reducing potential safety hazards.

- Greater flexibility – surveyors can work from unknown positions and still capture accurate data.

- Graphical visualization – allows for real-time review of calculations and can graphically show strong resection geometry or weak geometry.

- Improved efficiency – eliminates the need for resurveying in case of minor observation discrepancies.

- Recalculation options – incorrect or obstructed observations can be disregarded while maintaining valid results.

- Applications beyond mining – useful for civil engineers on construction sites where access is blocked by equipment.

The new feature will be rolled out as a general upgrade to all clients, saving time and costs while improving the accuracy and reliability of survey data.

This improved functionality is part of our ongoing effort to provide practical, high-impact software solutions for the mining industry. From survey management to risk assessment, production planning, and compliance tracking, Syncromine offers an integrated approach to mine management.

If you would like to hear more about this functionality, reach out to our team to set up a demo.